The Dana Z. Anderson group has developed a microchip-based system that not only rapidly produces Bose-Einstein condensates (BECs), but also is compact and transportable. The complete working system easily fits on an average-sized rolling cart. This technology opens the door to using ultracold matter in gravity sensors, atomic clocks, inertial sensors, as well as in electric- and magnetic-field sensing. Research associate Dan Farkas demonstrated the new system at the American Physical Society’s March 2010 meeting, held in Portland, Oregon, March 15–19.

To perfect the new compact BEC transporter, Farkas worked closely with Fellow Dana Z. Anderson, graduate students Kai Hudek, Evan Salim, and Stephen Segal, and Matthew Squires, who received his Ph.D. from CU in 2008. The Anderson group has been working on different aspects of this new technology for more than a decade.

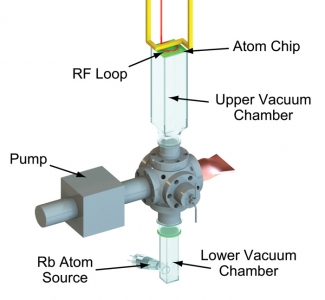

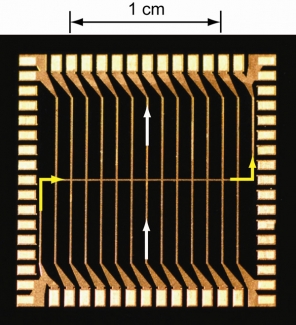

Key components of the new system include the two-chamber vacuum cell and an innovative atom-chip design. The new vacuum cell took the Anderson group more than a decade to perfect. Researchers built and tested more than 70 different prototypes before coming up with a design that provides the ultrahigh vacuum quality needed in the new portable system. The new vacuum cell is 10–20 times smaller than its conventional counterparts. It also serves as the platform for the atom chip where the BECs are made. Plus, the cell is now standardized, making it a good candidate for commercialization.

The Physics Frontiers Centers (PFC) program supports university-based centers and institutes where the collective efforts of a larger group of individuals can enable transformational advances in the most promising research areas. The program is designed to foster major breakthroughs at the intellectual frontiers of physics by providing needed resources such as combinations of talents, skills, disciplines, and/or specialized infrastructure, not usually available to individual investigators or small groups, in an environment in which the collective efforts of the larger group can be shown to be seminal to promoting significant progress in the science and the education of students. PFCs also include creative, substantive activities aimed at enhancing education, broadening participation of traditionally underrepresented groups, and outreach to the scientific community and general public.

The Physics Frontiers Centers (PFC) program supports university-based centers and institutes where the collective efforts of a larger group of individuals can enable transformational advances in the most promising research areas. The program is designed to foster major breakthroughs at the intellectual frontiers of physics by providing needed resources such as combinations of talents, skills, disciplines, and/or specialized infrastructure, not usually available to individual investigators or small groups, in an environment in which the collective efforts of the larger group can be shown to be seminal to promoting significant progress in the science and the education of students. PFCs also include creative, substantive activities aimed at enhancing education, broadening participation of traditionally underrepresented groups, and outreach to the scientific community and general public.