Extracting the full mechanical properties of ultrathin films and nanostructured materials

The demand for faster, more efficient, and more compact nanoelectronic devices, like smartphone chips, requires engineers to develop increasingly complex designs. To achieve this, engineers use layer upon layer of very thin films – as thin as only a couple strands of DNA – with impurities added, to tailor the function. However, the presence of these necessary impurities and extreme thinness degrades the material strength, reducing its performance and making it more likely to fail.

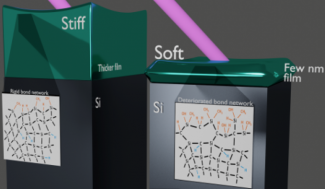

Figure. Full characterization of mechanical properties of ~5 nm films to uncover the influence of dopants and surfaces. As the layers thin, the mechanical properties dramatically deteriorate, becoming nearly 10 times flimsier than expected. Additionally, the presence of impurities can be more detrimental to the film’s strength than the effect of its thinning.

To date, it was simply not possible to test the stiffness or compressibility of the thinnest of these ultra-thin films. Now, by using high harmonic EUV beams, we were finally able to measure the mechanical properties of 5nm films. What we learned was surprising: as the layers thin, the mechanical properties dramatically deteriorate, becoming nearly 10 times flimsier than expected. Additionally, the presence of impurities can be more detrimental to the film’s strength than the effect of its thinning. These findings will influence the design of next generation electronic and other nanoscale devices.

In related research, we also studied metalattices - which are artificial 3D solids, periodic on sub-100nm length scales, that enable the functional properties of materials to be tuned. However, because of their complex structure, predicting, and characterizing their properties is challenging. We demonstrated the first nondestructive measurements of the mechanical and structural properties of metalattices with feature sizes down to 14 nm. By monitoring the time-dependent diffraction of short wavelength light from laser-excited acoustic waves in the metalattices, we extract their acoustic dispersion, Young’s modulus, filling fraction, and thicknesses. Our measurements are in excellent agreement with macroscopic predictions and potentially destructive techniques such as nanoindentation and scanning electron microscopy, with increased accuracy over larger areas. This is interesting because the transport properties of these metalattices do not obey bulk predictions. Finally, this approach is the only way to validate the filling fraction of metalattices over macroscopic areas. These combined capabilities can enable accurate synthesis of nano-enhanced materials.

The Physics Frontiers Centers (PFC) program supports university-based centers and institutes where the collective efforts of a larger group of individuals can enable transformational advances in the most promising research areas. The program is designed to foster major breakthroughs at the intellectual frontiers of physics by providing needed resources such as combinations of talents, skills, disciplines, and/or specialized infrastructure, not usually available to individual investigators or small groups, in an environment in which the collective efforts of the larger group can be shown to be seminal to promoting significant progress in the science and the education of students. PFCs also include creative, substantive activities aimed at enhancing education, broadening participation of traditionally underrepresented groups, and outreach to the scientific community and general public.

The Physics Frontiers Centers (PFC) program supports university-based centers and institutes where the collective efforts of a larger group of individuals can enable transformational advances in the most promising research areas. The program is designed to foster major breakthroughs at the intellectual frontiers of physics by providing needed resources such as combinations of talents, skills, disciplines, and/or specialized infrastructure, not usually available to individual investigators or small groups, in an environment in which the collective efforts of the larger group can be shown to be seminal to promoting significant progress in the science and the education of students. PFCs also include creative, substantive activities aimed at enhancing education, broadening participation of traditionally underrepresented groups, and outreach to the scientific community and general public.